Smart Technology Awakens a New Sensory World of Apparel

As technology continues to advance, textile engineering and material science are becoming deeply integrated with fashion design, giving rise to a new wearables revolution centered on smart fabrics. This article provides a systematic and professional overview of smart textiles—including water-activated pattern fabrics, thermochromic (temperature-sensitive) color-changing fabrics, and light-responsive pattern fabrics—from the perspectives of technical principles, application scenarios, industrial ecosystem, and future development trends. The goal is to present the latest progress and long-term value of this field through a pragmatic and industry-oriented lens.

1. Core Principles and Technical Pathways of Smart Fabrics

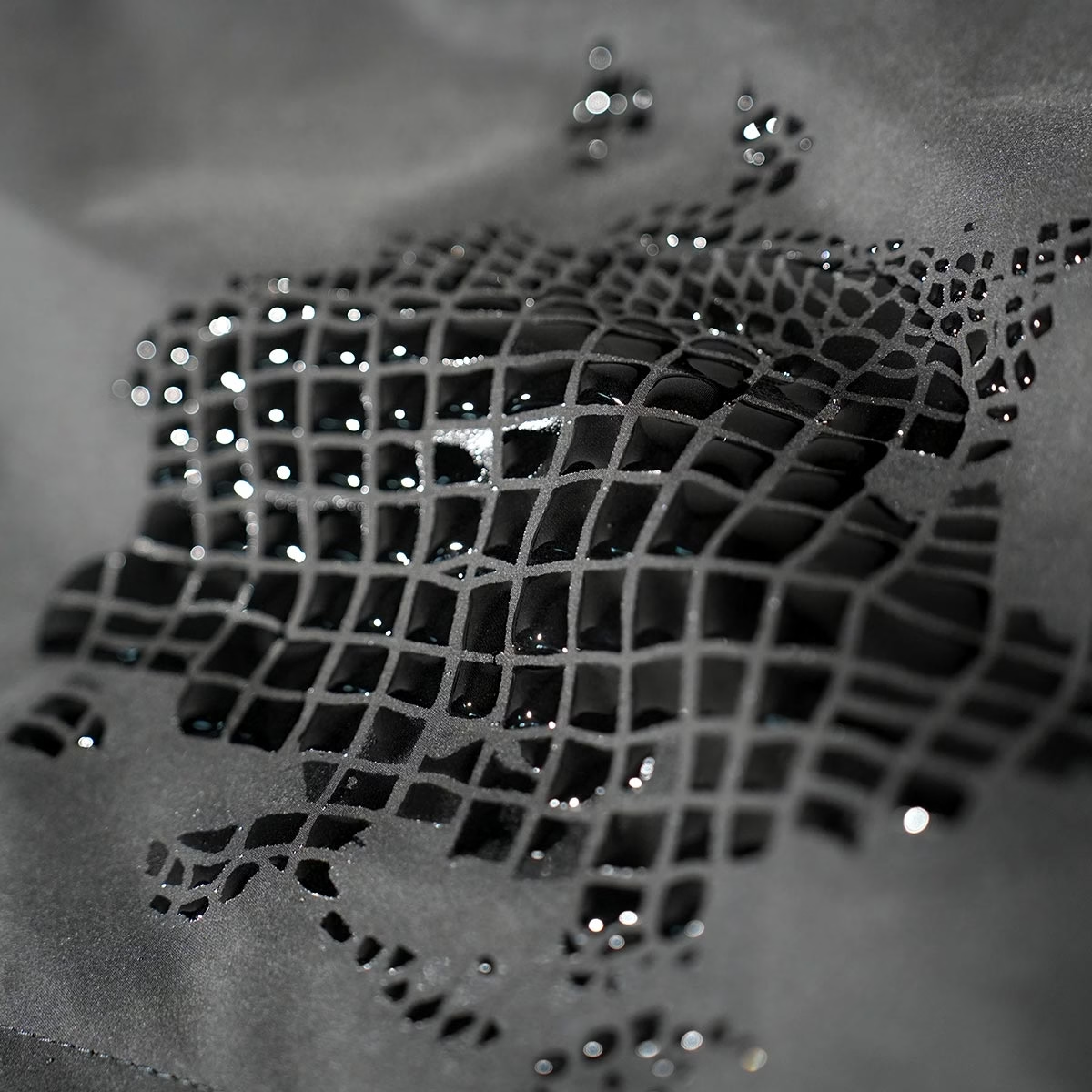

Water-Activated Pattern Fabrics

Principle:

These fabrics typically feature surface layers engineered with combined hydrophobic–hydrophilic microstructures. When exposed to water, moisture spreads across the surface, triggering reversible phase changes or permeability shifts that reveal previously hidden patterns. Key approaches include microcapsule technology, thermally expandable structures, surface modification using hydrophilic functional groups (such as hydroxyl or carboxyl groups), and selective dissolution or self-assembly of dip-coated pattern materials.

Environmental performance and repeatability are critical considerations. Ideal materials must balance wash durability, long-term stability, repeatable visibility, and effective concealment when dry.

Application Focus:

Commonly used in outerwear, sportswear, and rain gear, these fabrics combine functional performance with visual surprise. Future development directions include improving contrast, reducing response time, expanding the color and pattern library, and enhancing stability across diverse climate conditions.

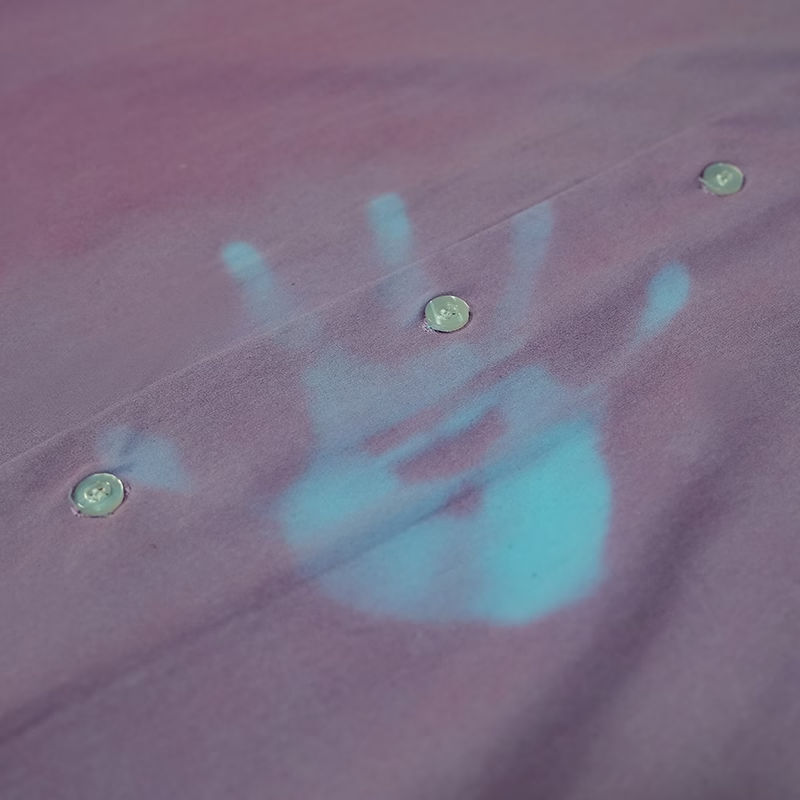

Thermochromic (Temperature-Sensitive) Color-Changing Fabrics

Principle:

These fabrics employ thermochromic materials such as temperature-responsive polymers, reversible thermochromic pigments, or liquid crystal microcapsules. Changes in ambient or body temperature induce reversible molecular structural transformations, resulting in visible color shifts. Key technical challenges include precise control of response temperature ranges, fast reaction speed, and long-term color stability (resistance to light, washing, and chemicals).

Application Focus:

Beyond aesthetics, thermochromic fabrics can serve as sensory feedback interfaces—indicating thermal comfort levels or abnormal body temperature. Future technical paths emphasize finer color gradation, passive low-energy responses (without external power), and deeper integration with sensors to enable richer physiological and emotional feedback.

Light-Responsive Pattern Fabrics

Principle:

By embedding photosensitive materials—such as fluorescent dyes, polarized molecules, or photochromic films—within or on the surface of textiles, patterns emerge under specific lighting conditions. Activation may occur through visible light or ultraviolet exposure, often enhanced through multilayer structures that create hidden or gradient visual effects.

Application Focus:

These fabrics show strong potential in everyday fashion, nighttime safety apparel, and runway presentations. Current challenges include dependence on light sources, pattern stability, and color consistency. Future improvements may involve self-luminous materials, solar-powered energy systems, and ambient-light-responsive solutions that reduce reliance on specific light conditions.

2.Key Considerations in Design and Manufacturing

Material Compatibility and Durability

Smart textile innovation often relies on multilayer material architectures. Achieving advanced functionality without compromising hand feel, breathability, softness, or wash durability remains a central challenge. Lamination, bonding, and thermal pressing techniques must ensure structural integrity while preventing performance degradation or layer delamination during wear and laundering.

Sustainability and Environmental Responsibility

Sustainability has become a defining industry priority. For smart fabrics, this extends beyond recyclable raw materials to include energy consumption, wastewater discharge, and end-of-life recycling. Active research areas include biodegradable polymers, solvent-free coating processes, low-water dyeing technologies, and circular economy–oriented recycling systems.

Edge Computing and Embedded Data Processing

When sensing and responsive capabilities are introduced, fabrics must integrate electronics, sensors, circuits, and data-processing modules. To preserve comfort and aesthetics, solutions such as flexible electronics, edge computing, and seamless wearable integration are essential. The long-term trend points toward higher integration, lower power consumption, and autonomous interaction without reliance on external devices.

Manufacturing Scalability

Scaling from prototypes to mass production significantly raises technical demands. Manufacturing processes must tightly control material stability and visual consistency. Efficient coordination across material suppliers, coating, printing, and finishing stages is required to manage lead times and enable standardized production across regions.

3.Application Scenarios and Industry Ecosystem

Fashion and Everyday Wear

In daily apparel, smart fabrics enhance personalization and situational expression. Water- and light-activated patterns allow garments to transform visually across environments, strengthening brand storytelling and customer engagement. Thermochromic fabrics add emotional interactivity, fostering a deeper connection between wearer and garment.

Professional and Outdoor Applications

Outdoor apparel demands superior waterproofing, breathability, and durability. Water-activated rainwear and thermochromic protective garments offer both functional performance and enhanced visibility, contributing to safety and usability. Coordinated design of breathable membranes and protective coatings will remain a key competitive advantage.

Safety and Security Fields

In transportation, construction, and emergency services, light- and temperature-responsive textiles can function as warning systems and visual identifiers. Self-luminous or reactive color-change mechanisms improve visibility and response efficiency in critical situations.

Medical and Rehabilitation Applications

Thermo-responsive fabrics can assist in monitoring body temperature, blood flow, and other physiological indicators, supporting early health warnings. In wearable medical technology, lightweight, seamless, and integrated sensing solutions represent a major breakthrough opportunity.

4.Market Outlook and Key Challenges

Market Demand and Growth Potential

Global interest in wearable technology and smart apparel continues to rise. Consumer demand for personalization, interactivity, and sustainability is accelerating market expansion. Brands that successfully merge technology with fashion can achieve strong differentiation and enhanced brand value.

Technical and Regulatory Challenges

When smart fabrics involve data collection or physiological monitoring, compliance with data privacy, security, and ethical regulations becomes essential. Companies must establish robust compliance frameworks that meet standards across different markets and jurisdictions.

Supply Chain and Cost Structure

Smart fabrics typically carry higher costs and more complex production processes than conventional textiles. Achieving scale requires mature cost structures covering materials, equipment, process stability, and after-sales support.

5.Future Development Directions

Integrated Material Innovation

The integration of advanced polymers, nanomaterials, and biomimetic structures will enhance performance while reducing environmental impact. Multi-material synergistic design will become mainstream, enabling higher contrast effects, faster responses, and longer service life.

Intelligent Interaction and Emotional Experience

Future fabrics will not only be visually responsive but also communicative. By integrating tactile, visual, thermal, and even olfactory signals, garments will support multimodal interaction—becoming expressive interfaces for emotional and social communication.

Circular Economy and Recycling Systems

Designing for recyclability from the outset—through modular, detachable, and mono-material strategies—will be essential. Efficient separation and reprocessing at the recycling stage can significantly reduce reliance on virgin resources.

Data-Driven Design Methodologies

By leveraging big data, computer vision, and machine learning, designers can analyze how wear behavior and environmental conditions influence fabric performance. Data-driven design will improve consistency, durability, and personalization of smart textile applications.

Strategic OEM/ODM Insights: Perspectives from Yaliapparel

Within the smart-fabric-driven apparel transformation, Yaliapparel has identified three converging trends shaping the market:

- Deep integration of materials and manufacturing processes

- Emotional and personalized brand expression

- Coordinated development of sustainability and regulatory compliance

Technologies such as water-activated patterns, thermochromic color change, and light-responsive graphics inject garments with dynamic storytelling capabilities, transforming each piece into a narrative-driven product. For OEM/ODM Clothing for private brands, this represents a new arena where differentiation is defined by innovation and loyalty is driven by experience.

Strategic Recommendations for Creative OEM/ODM Clothing Customization

- Brand Positioning Aligned with Technical Storytelling

Bind functional textile properties to brand narratives—such as “the explorer’s color-shifting jacket” or “patterns revealed in the rain.” Transparent, traceable material and process documentation strengthens consumer trust. - Modular Customization Frameworks

Offer modular combinations of water-activated, thermochromic, and light-responsive technologies. This enables flexible configuration within a single collection, reducing development risk and accelerating time to market. - Experience-Driven Small-Batch Pilot Production

Using small-batch, rapid-iteration ODM solutions to quickly validate market response and key indicators such as the durability of colors/patterns and washing stability, thereby increasing the brand’s success rate when launching new products. - Sustainability and Circular Economy

Prioritizing the use of recyclable and low-environmental-impact materials, considering ease of disassembly, modularization, and recycling pathways during design to enhance the brand’s competitiveness in compliance and environmental protection, and increase consumer recognition of the brand. - Full-chain Brand Protection and Traceability

Using digital labels and blockchain and other methods to record the material source, processing steps, and functional parameters of each customized product, ensuring the consistency and anti-counterfeiting capabilities of the brand value in the global market

OEM/ODM private brand apparel efficient customization service can not only quickly transform the innovation of smart fabrics into marketable products but also strengthen the uniqueness and price protection capabilities of its own brand with the value proposition of “customization + high experience + transparent traceability.” In the future, wearing clothes will no longer be just a physical function of covering the body, but will become an interactive carrier for brands and consumers to participate in together, promoting brands to achieve sustained growth and long-term competitiveness in the global market.