Camouflage Streetwear: A Dual-Track Evolution from Jungle to City

At Yali Clothing, with over 20 years of garment manufacturing experience, camouflage has never been just a simple pattern, but a language – a language about power and boundaries. This season, we bring the “law of the jungle” into the city, turning the streets into new hunting grounds. Camouflage is more than just appearance; it’s a synthesis of a complete set of techniques and manufacturing philosophies, designed specifically for mass production, customization, and efficient delivery.

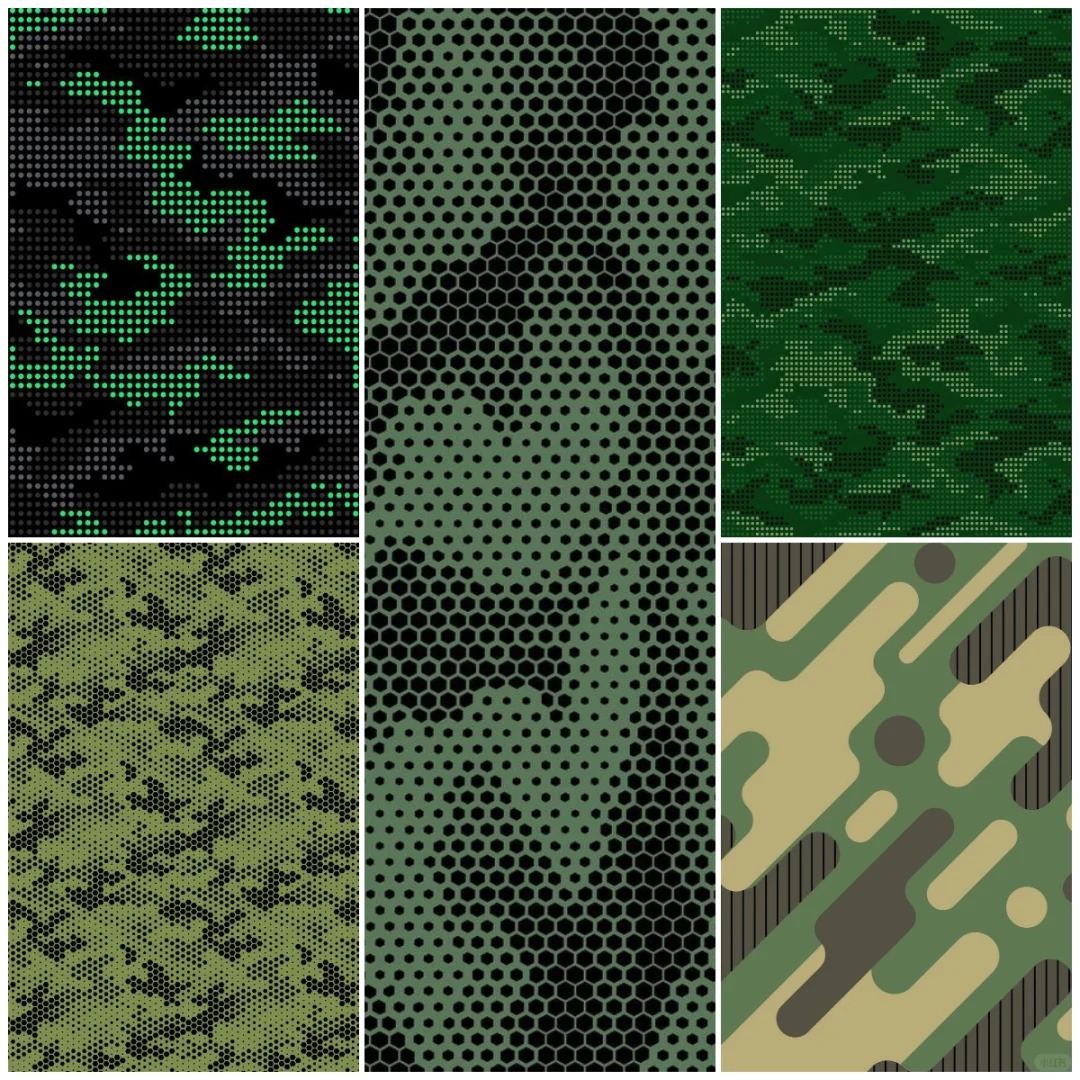

Camouflage Enters the Cyber Age

Glitch Art Visual Impact: On a large-scale production line, unique breakpoints and misaligned color blocks create pixel-level distortion aesthetics, ensuring that each garment has differentiated recognition within the same batch, avoiding the risk of homogenization. Virtual Reality Color Hedging: High-saturation contrasting colors and gloss finishes, combined with aggregation technology, create color stability that is both attractive and washable, suitable for long-term batch production. Pixelated Pattern Deconstruction: From pixel grids to fractured lines, a controlled grid splitting process is used to ensure visual consistency across different sizes and fabric densities. Rewriting Street Rules with Code: Embedding digital design language into the cutting and sewing process to improve version iteration speed and shorten the cycle from sample to bulk goods.

Fit & Fabric

Oversized Silhouette Constructs Mobile Territory: With a balance between wearability and activity as the core, sufficient range of motion is provided to ensure stability during multi-size mass production. Industrial-Grade Fabrics Provide Dual Armor: Durable, washable, and wrinkle-resistant blends and high-density fabrics are selected to enhance the daily durability of the clothing. Vintage Wash Creates Battle Scars: A combination of controlled water, surfactant, and finishing processes makes the vintage effect natural and long-lasting, suitable for large-volume stability. Damaged Treatment as Battle Achievement Badges: Every damage, tear, and abrasion is standardized to ensure consistent mass production while retaining personalized recognition.

Production & Quality Control Key Points

Standardized Process Route: From sample to bulk goods, a clear process node and inspection point are established to ensure a high degree of consistency in color, quantity, and specifications between different batches. Traceable Material System: Raw material batch numbers, fabric roll numbers, and dyeing and finishing batches are recorded in real time to facilitate OEM/ODM docking and after-sales traceability. End-to-End Customization Capabilities: While retaining an efficient mass production line, flexible options are provided for batch customization, such as custom labels, packaging, logos, and small-batch samples.

Conclusion:

When camouflage meets the city, people see not just color, but an attitude, a rewriting of “rules.” For apparel brands, how to maintain uniqueness in mass production while ensuring efficient and stable delivery is the core challenge today.

Yali Clothing has professional trend insights and mature OEM/ODM mass customization capabilities in the camouflage streetwear field. We have 20+ years of garment production experience and are trusted by over 300+ well-known brands in Europe, North America, and other regions. Compared with the traditional model in the garment manufacturing industry, the production efficiency is significantly 38% higher, the cost is more competitive, and it has more friendly advantages in highly personalized batch customization speed and flexibility. If your brand is looking for a trustworthy partner to quickly amplify and implement ideas, our ready-made garment line and customization services are your reliable choice.